This method allows for flexibility in cost allocation, ensuring that the unique characteristics of each product’s production process are accounted for accurately. At its core, process costing is about dividing the total production cost of a manufacturing process into smaller parts to determine the cost per unit. This approach is particularly useful in industries where products are more or less indistinguishable from one another.

- Expenses can be allocated to different processes on rational basis and accurate cost, thus, can be ascertained.

- (ii) All the direct and indirect expenses related to a specific process are shown in the debit of the concerned process.

- These costs are summed up for a given period, typically a month, to determine the total cost incurred by each department.

- Cost Calculation – In process costing costs are calculated on the basis of period after the completion of the process.

- Units in WIP must be converted to a base which can be equated with completed production.

If there is normal loss, the loss is borne by the good units completed, thus increasing the average cost per unit.

Different methods are used in process costing to allocate production costs effectively. The choice of method depends on how a business tracks inventory and expenses over time. Enter process costing — a systematic way to assign costs to products in industries where goods are mass-produced in process costing a continuous flow.

- (3) Where goods pass through two or more distinct processes to completion.

- To price effectively, everything it takes to manufacture a product must be accounted for.

- Process costing in manufacturing is best suited for industries that produce large volumes of uniform products through continuous or repetitive operations.

- Modern manufacturing software integrates production data collection with cost accounting procedures, ensuring accurate and timely cost calculations.

- Since production runs continuously, some lenses remain in process at the end of each period.

- These costs are often added at specific production points rather than continuously.

Process Costing Examples in Manufacturing

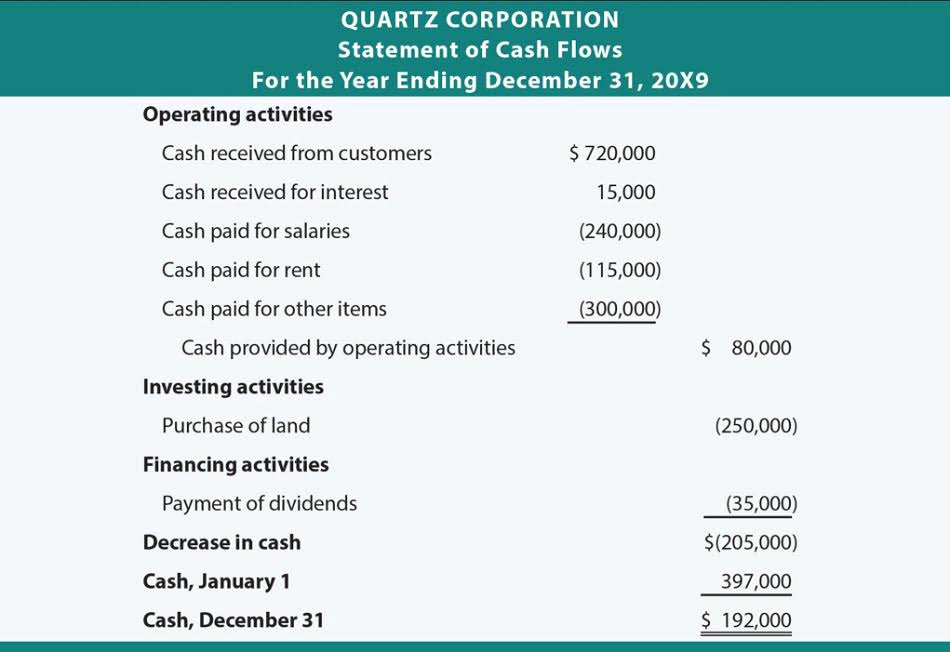

Materials are Cash Flow Statement added at the beginning of production, while conversion costs occur uniformly throughout the process. From a practical standpoint, process costing requires less detailed record-keeping than job costing, making it more cost-effective to implement and maintain. However, it provides less granular cost information for individual products or customer orders.

- Materials costs typically enter production at specific points rather than continuously throughout the process.

- Because every bag is the same, the total production cost is averaged across all units.

- Scrap value of normal loss account is credited to process account and scrap value of units representing abnormal loss is credited to abnormal loss account.

- Depending on the nature of data and requirement, quantity column may be dispensed with.

Process Costing: Types, Benefits, Steps, and Examples

Finished products at the end are homogeneous i.e., indistinguishable. Production for Stock and Sale – Output is uniform and is usually manufactured for stock and then sell and not for the specific order. In other words, in these industries, a process is subdivided into a number of parts, each of which is known as an operation. For example, when cycle mudguards are to be made, the steel sheets will be cut into proper strips and then shaped according to the design and machined before being finally polished.

Process Costing – Determination of Unit Cost

- Simple mathematical errors can distort cost allocations and impact financial reporting accuracy.

- As the manufacturing landscape continues to evolve, the role of process costing is only expected to grow in importance.

- This unit cost applies to all production regardless of when costs were originally incurred.

- Unlike process costing in manufacturing, where cost per unit is averaged, job costing provides a more granular view of profitability and efficiency on a per-project basis.

- By using FIFO process costing, one of the most popular costing approaches, we can calculate a more accurate product costing.

- The entity has provided the following information & wants to calculate the cost involved in each manufacturing step.

Inaccurate completion estimates directly impact cost allocation between completed units and ending inventory, affecting both cost of goods sold and inventory values. Equivalent unit calculations show 50,000 units for materials (46,000 completed + 4,000 started) and 48,400 units for conversion (1,400 to complete beginning + 46,000 completed + 2,400 ending equivalent units). The physical flow analysis revealed 2,000 bottles in beginning work-in-process (80% complete), 98,000 bottles started and completed during March, and 1,500 bottles in ending work-in-process (60% complete).

Steps of process costing

(4) Where output of one process becomes https://dailycitizenvoice.com/adjusting-entries-in-accounting-beginner-s-guide/ the input of the subsequent processes. (3) Where goods pass through two or more distinct processes to completion. Sign into Fisbowl Communities and gain access to support requests, product documentation and software downloads.

Job costing suits custom manufacturing, construction projects, professional services, or any situation where products or services are unique and require individual cost tracking. A custom furniture manufacturer, for example, would use job costing to track the specific materials and labor required for each piece. Chemical manufacturing perfectly exemplifies process costing applications. Raw materials like salicylic acid and acetic anhydride enter the first process where they’re combined and heated. The resulting compound moves to the next process for purification, then to tablet formation, coating, and finally packaging. Each process adds costs (materials, labor, overhead) that need to be tracked and allocated to the final product.